As I mentioned in a previous post, some of the work on the spinner plates and spinner itself was done prior to the engine being installed. This definitely saved me some time and I got right to work with the final fitment once the prop was on the engine. I removed the expansion gasket IAW the plans by drilling a #30 hole and then using a screwdriver to deform the plug enough so that it could be pulled out. Whenever you're removing something from the engine (e.g. exhaust covers, spark plugs, expansion plug) be ready for plenty of preservative oil to come out behind it. There's a lot that comes out of the sniffle drain for a long period. Every time you shift the plane around, more oil settles and will end up on the floor if you're not ready for it.

I was very lucky to meet a gentleman that owned an FAA repair station for 20 years. He lives in my neighborhood and was happy to stop by and give me some advice and pointers. He mentioned that Hartzell recently changed their safety wire requirements for the spinner to say .032" is the minimum wire required to secure the prop bolts. I had already used .040", and it's not easy to work with. If I have to revisit this at some point, I'll be backing off to .032 for sure.

I hate the magnet approach to finding holes through the opaque fiberglass. As I've mentioned previously, I have about a 75% success rate in finding the holes on the first try with that method. It's extremely frustrating to drill that hole and see nothing but aluminum on the other side with no sign of the hole anywhere around the edges. I guess I'm just not experienced enough with getting the magnet to "settle" in the right spot so that I can drill accurately.

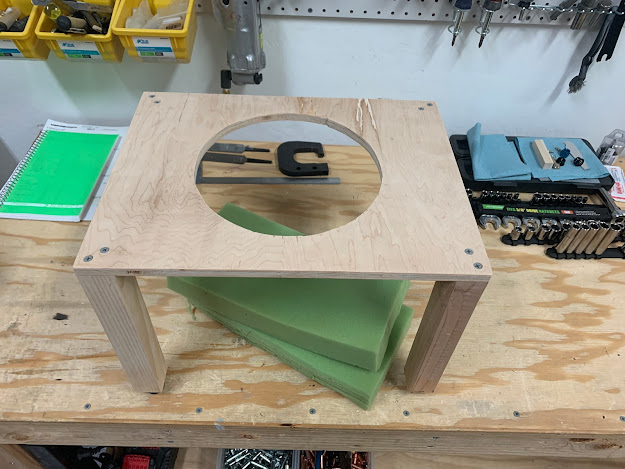

So when it came to the spinner, I latched on to an ingenious option that I saw on a builders group. I used my woodworking tools to create a leveling stand to that I could accurately mark the alignment of the holes that already exist on the front spinner. I then leveled the stand so that a fine point sharpie pen would draw a line bisecting the holes at each location. The trick was removing the stand (not moving ANYTHING) and then putting the spinner on the propeller so that I could draw the hole positions. I made one small error and only one hole wasn't quite where it needed to be initially (I could see the hole, it just wasn't centered). I corrected that and had PERFECT locations for the remaining 5 holes. I fixed the errant location with some epoxy flox mix while I was working on the snorkel later on.

Nobody move!

Drilled through the spinner!

One hole -slightly- low. Building on!

No comments:

Post a Comment